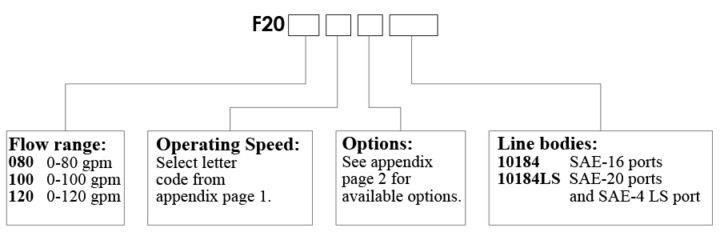

Function

- Motor driven, variable orifice, restrictive type, hydraulic flow control, non-pressure compensated. Pressure balanced, bi-directional flow.

Operating Pressure

- 3000 psi maximum differential

- Consult factory for higher operating pressures

Flow Ranges

Based on 100 PSI pressure differential with valve fully open. See pressure drop curves for additional application data

- 080 0-80 gpm (Equivalent to Ø.55” orifice at full open)

- 100 0-100 gpm (Equivalent to Ø.60” orifice at full open)

- 120 0-120 gpm (Equivalent to Ø.66” orifice at full open)

- Custom ranges are available upon request

Voltage

- 12 & 24 VDC

Construction

- Cage, body and spool: Steel, exposed parts plated

- Motor housing assembly: Anodized aluminum

- Standard line bodies are aluminum

- Steel bodies are available upon request

Seal Material

- Buna N and polyurethane standard

- Viton optional

Current Draw

- 0.8 amp when powered at 12 volts

- 1.0 amp when powered at 24 volts

Internal Leakage

- 15 cubic inch per minute per 1000 psi

Temperature

- -40 to 120°C